Slag Removal Processes & Tools

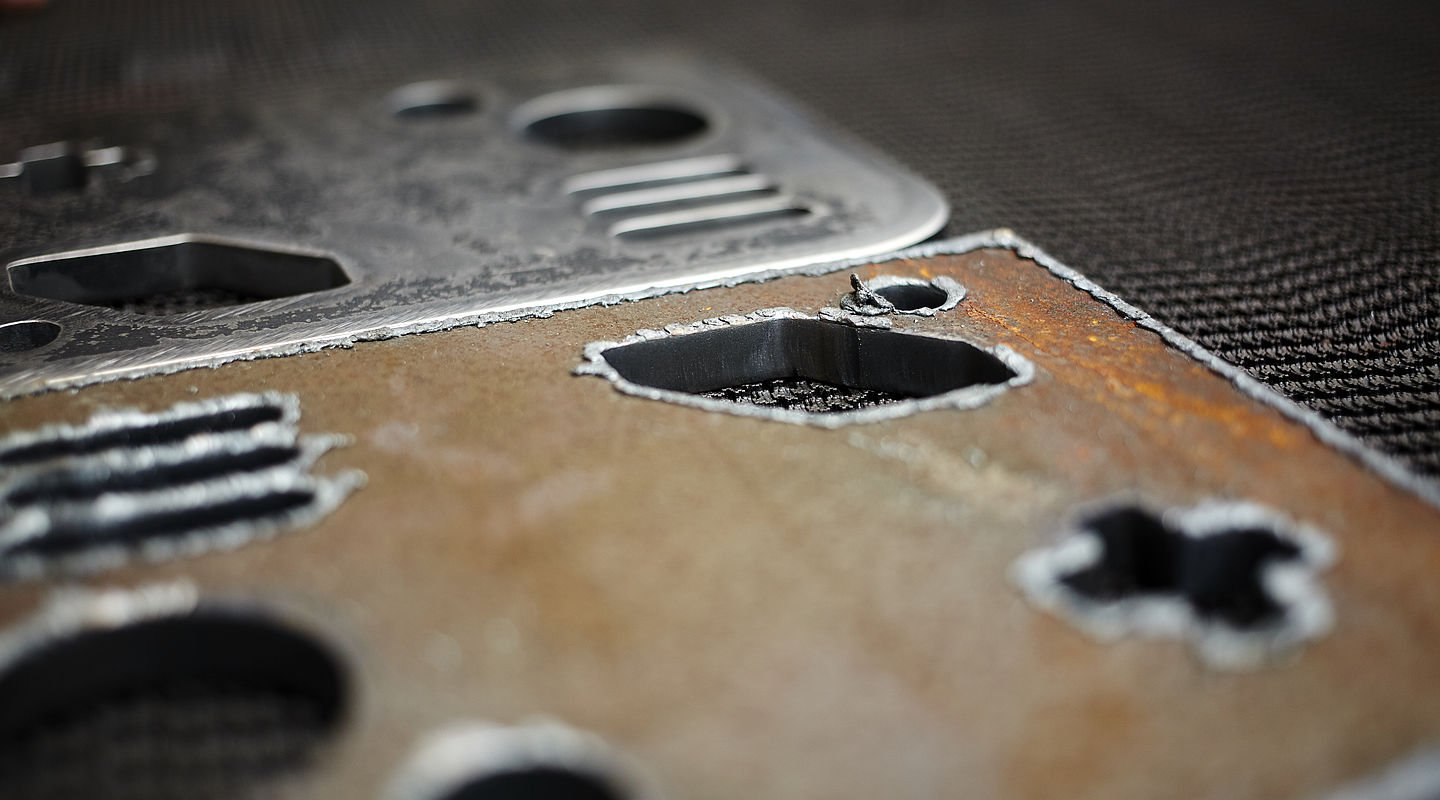

Slag or dross is not fully ejected material from the kerf and happens often when thicker sheet metal parts or plates are cut. If the waste material can be chipped off by lateral force we call it slag removal. The transition from burr to slag is fluid. However, as different tools are used in edge processing, we also distinguish between deburring (grinding) and slag removal (chipping off) processes.

Slag removal with the slag hammer.

Slag usually forms on thick plasma and oxyfuel-cut parts. There are two reasons why grinding off slag does not make sense. First, slag cannot be completely removed, because only up to a certain level can be grinded down and the rest is pressed down. Second, there is an enormous amount of abrasive is used due to the slow grinding process which results in high abrasive costs.

The preferred method for slag removal is to literally chip it off the part with carbide pins. The slag hammer hits the side of the slag at high speed and breaks it off the edge. This robust procedure uses discs equipped with carbide pins that rotate and oscillate across the part. The part is held by rollers that move the part over the tools.

Various tool designs are available.

Additional information.

Contacts.

Andreas Zimmer

Application Engineer

P: +1 513 985-0500

Keep up with the leaders: with our newsletter.

Machines in use at customers, practical tips, events and much more: keep up with the news in the ARKU world.

To the registration

Hotline.

We are there for you around the clock and seven days a week with our 24/7 hotline.

Standard data rates may apply

Do you need advice?

If you are not sure which machine is the best choice for you, we are happy to assist you.